Detecting and Fixing Leaks in Pneumatic Systems

Leaks can be a significant source of wasted energy in an industrial compressed air system, sometimes wasting 20-30% of a compressor’s output*. Not only does this account for a source of wasted energy, but leaks can also contribute to other operating losses.

Firstly, leaks can cause a drop in system pressure, resulting in pneumatic air tools functioning less efficiently and thereby adversely affecting production.

In addition, by forcing the equipment to cycle more frequency to compensate for the energy lost from air leaks, the life of almost all system equipment can be drastically shortened, including the compressors themselves. Increased running time and equipment stress can also lead to additional maintenance requirements, increased unscheduled downtime, and additional costs.

*Marshall, R. 2010, ‘Finding and Fixing Leaks’, Compressed Air Best Practices

Solutions

The best way to take control of air leaks in your pneumatic system is to establish a preventative maintenance routine. Regular inspections of your facility are essential to identify leaks and fix them early before they cause problems.

Traditional leak detection methods are time consuming, inefficient, and extremely limited. Many companies still opt for the soapy water or close listening methods using ultrasonic tools, both of which are slow and require production to shut down during the inspection, resulting in significant downtime losses.

Using Traditional Ultrasonic Tools:

- Involves a trained inspector with an educated ear listening to identify miniscule noises and determine whether they are originating from leaks.

- Requires experience, training, and certifications.

- Involves point by point meticulous inspections, and the use of Snoop Tests (soapy bubbles) to verify detected leaks.

- Manual tagging is required to track leaks.

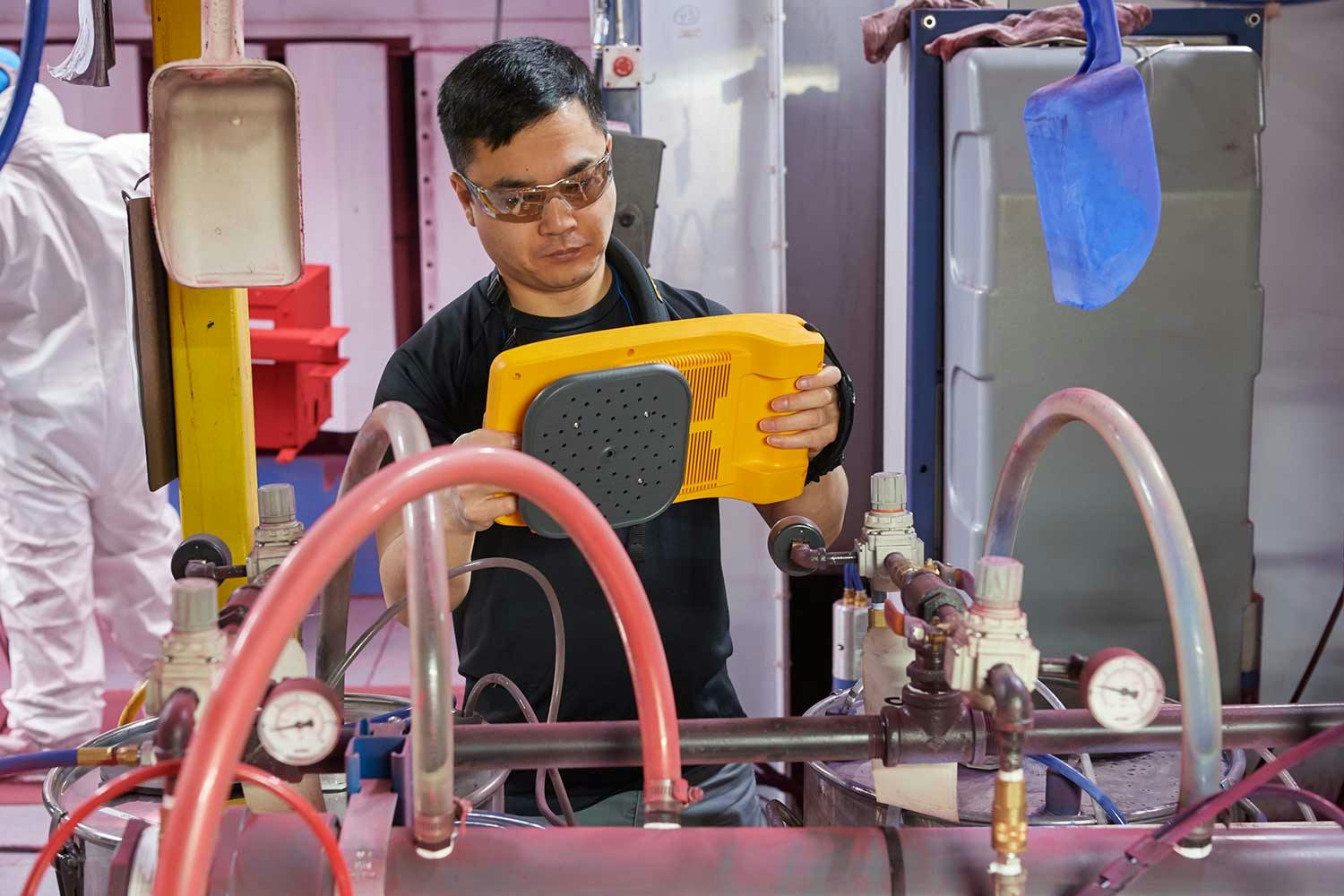

The Fluke ii905 Sonic Industrial Imager and ii915 Precision Acoustic Imager can detect leaks up to 10 times faster than these traditional methods and do not require any specialist training or certifications to use.

Using Fluke ii905 and ii915 Acoustic Imagers:

- Turn on the imager

- Scan a large area

- See the leak on the screen

- Save and tag the result on the device

It really is that easy.

Inspect during operations

Finding compressed air line leaks is easy—if you can hear them. Most people can’t hear compressed air leaks in a completely quiet environment, let alone in a loud manufacturing plant. Even if you think you hear a leak, you will need to verify it, which means you need to be able to access it.

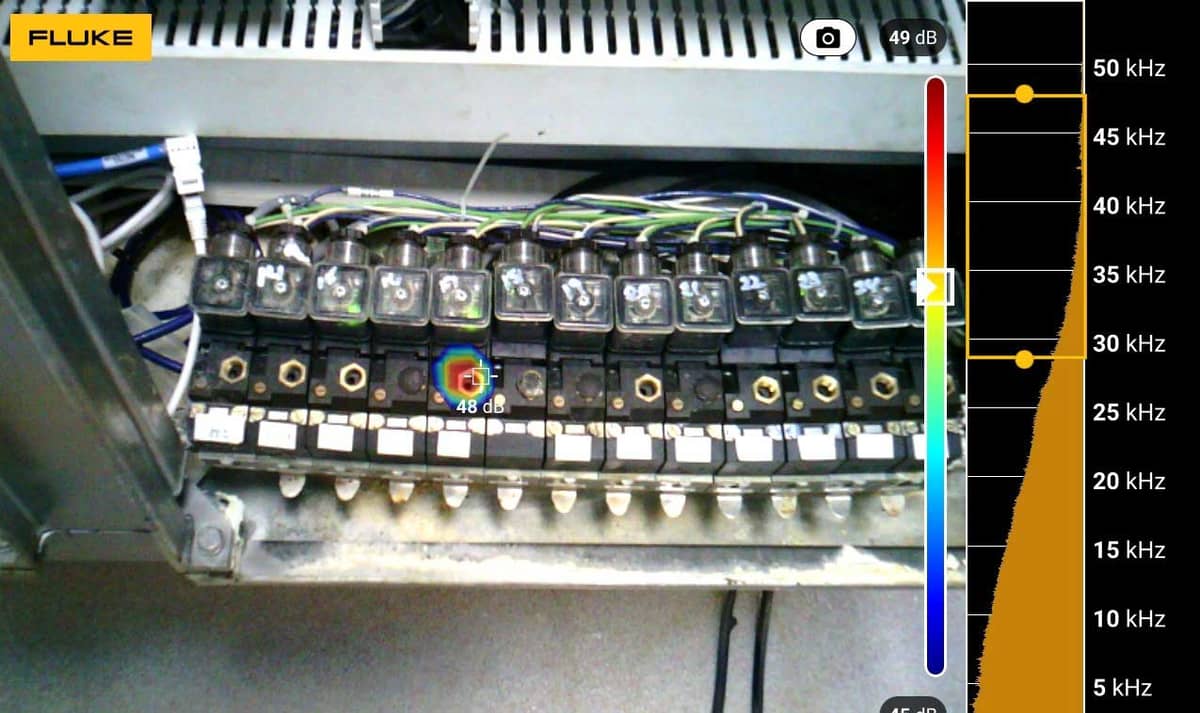

With the Fluke ii905 and ii915 it is possible to conduct entire leak inspections during ongoing operations. The device’s inbuilt array of sensitive microphones has been designed from the ground up to be able to isolate the distinct frequencies of compressed air leaks and filter out all extraneous production noises. With the Fluke ii905/ii915 in your maintenance arsenal, equipment downtime is a thing of the past.

Comprehensive inspections

With a detection distance of up to 70 metres (ii905) or 120 metres (ii915), and broad frequency range, it has never been easier to locate miniscule leaks. In facilities with overhead pipes and large machinery, the source of leaks can often be found in hard-to-reach or unsafe areas. In many cases these leaks remain hidden for extended periods of time, causing unseen losses much longer than they should. These problems simply do not exist with the Fluke ii905 and ii915, which use a visual SoundMap to instantly show you where leaks are occurring at a glance no matter where they might be, from the safety of the ground. You can even find multiple leaks on screen at a time.

See the value

We all know that unchecked leaks result in unseen costs, however it’s an arduous process to quantify and report on them. With the Fluke ii905’s and ii915’s LeakQ mode and report generator, the data you capture with the device can be instantly turned into a report analysing the size of detected leaks and their associated cost estimations. Now you can immediately see the value of each maintenance routine conducted.

Anyone can use it

What you see is what you get. If it looks like the Fluke ii905 and ii915 are easy to use, that’s because they are. In mere minutes any member of your maintenance team will be able to pick up this device and start locating leaks – no training required. Check it out for yourself in the 360° Virtual Demo.